Magnetic Condensing System for Cryogenic Engines

- :

Patent number: EP 1 367340 A3

Abstract

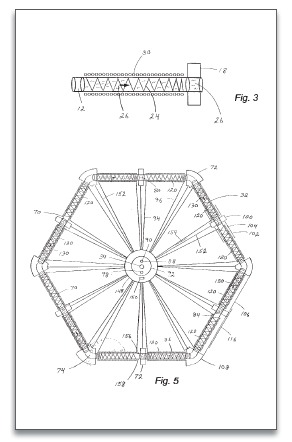

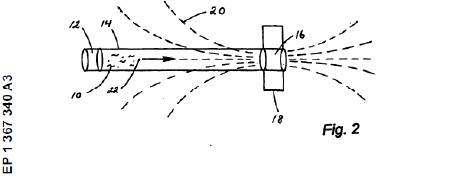

A method and apparatus is provided for generating an artificial heat sink below ambient temperature for a cryogenic condenser by isothermally magnetizing a paramagnetic fluid and removing the magnetic field thereby creating a temperature drop in the fluid by the magentocaloric effect. The heat of magnetization is converted into mechanical work by initially placing the fluid (10) inside a sealed chamber (12) with a door that opens to a conduit (14) leading into the bore of a superconducting solenoid (18). When the solenoid (18) is energized with current, it creates a strong axial magnetic (20) field that exerts magnetic attractive forces on the fluid (10) inside the chamber (12). When the fluid (10) is released by opening the door, it is accelerated through the conduit (14) toward the superconducting solenoid (18) where it becomes magnetized by the increasing strength of the magnetic field (20). By mounting a nonmagnetic urbine inside the conduit (14) between the solenoid (18) and the chamber (12), the kinetic energy of the accelerating flow stream, which is equal to the heat of magnetization, is converted into mechanical work thereby achieving isothermal magnetization. By removing the magnetic field after the fluid enters the bore of the solenoid, a temperature reduction is achieved thereby enabling the fluid to absorb heat in a cryogenic condenser.

Publication Date: 09.10.2009

Publication Kind: A

IPC: F25B 19/00

Applicant: MICHAEL ANDREW MINOVITCH

Inventors: MICHAEL ANDREW MINOVITCH

Priority Data: 10151537 21.05.2002 US

Related patent documents: PH12004501883, US20030218852, left; CN1662780, CA2486428, AU2003239545, JP2005526947, WO/2003/100330. PL203224, EP1367340. MA/a/2004/011475, PH1-2004-501883, KR1020050007556, RU2004137286

Patent number: WO/2003/100330A1

Abstract

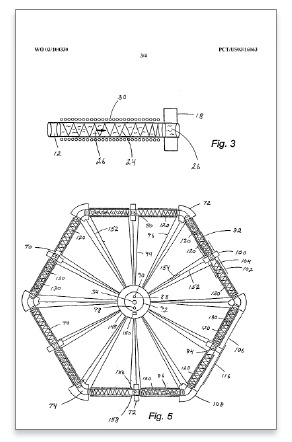

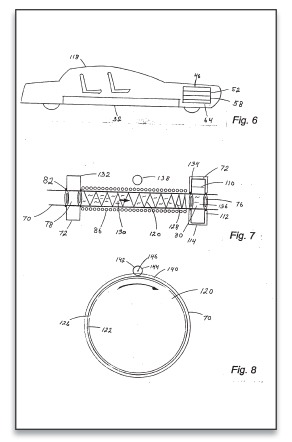

A method and apparatus is provided for generating an artificial heat sink below ambient temperature for a cryogenic condenser (32) by isothermally magnetizing a paramagnetic fluid and removing the magnetic field, thereby creating a temperature drop in the fluid by the magentocaloric effect. The heat of magnetization is converted into mechanical work by initially placing the fluid inside a sealed chamber (80) with a door (76) that opens to a conduit (70) leading into the bore of a superconducting solenoid (72). When the solenoid (72) is energized, it creates a strong axial magnetic field that exerts magnetic attractive forces on the fluid. When the fluid is released by opening the door (76), it is accelerated through the conduit (70) toward the superconducting solenoid where it becomes magnetized by the increasing strength of the magnetic field. By mounting a non-magnetic turbine (120) inside the conduit between the solenoid and the chamber, the kinetic energy of the accelerating flow stream, which is accelerating flow stream, which is equal to the heat of magnetization, is converted into mechanical work, thereby achieving isothermal magnetization. By removing the magnetic field after the fluid enters the bore of the solenoid, a temperature reduction is achieved thereby enabling the fluid to absorb heat in a cryogenic condenser.

Applicant and Inventor: Minovitch, Michael, A.

Agent: SEIBEL, Richard, D., LLP, Post Office Box 7068, Pasadena, CA 91109-7068 (US).

International Publication Date: 4 December 2003 (04.12.2003)

International Application Number: PCT/US03/16063

International Filing Date: 6 May 2003 (16.05.2003)

2003-05-16: Priority to AU2003239545A

2003-05-16: Priority to MXPA04011475A

2003-05-16: Priority to KR10-2004-7018884A

2003-05-16: Priority to CA002486428A

2003-05-16: Priority to JP2004507744A

2003-12-04: Publication of WO2003100330A1

Patent number: EP 1 367 340 A2

Abstract

A method and apparatus is provided for generating an artificial heat sink below ambient temperature for a cryogenic condenser by isothermally magnetizing a paramagnetic fluid and removing the magnetic field thereby creating a temperature drop in the fluid by the magentocaloric effect. The heat of magnetization is converted into mechanical work by initially placing the fluid (10) inside a sealed chamber (12) with a door that opens to a conduit (14) leading into the bore of a superconducting solenoid (18). When the solenoid (18) is energized with current, it creates a strong axial magnetic (20) field that exerts magnetic attractive forces on the fluid (10) inside the chamber (12). When the fluid (10) is released by opening the door, it is accelerated through the conduit (14) toward the superconducting solenoid (18) where it becomes magnetized by the increasing strength of the magnetic field (20). By mounting a non-magnetic turbine inside the conduit (14) between the solenoid (18) and the chamber (12), the kinetic energy of the accelerating flow stream, which is equal to the heat of magnetization, is converted into mechanical work thereby achieving isothermal magnetization. By removing the magnetic field after the fluid enters the bore of the solenoid, a temperature reduction is achieved thereby enabling the fluid to absorb heat in a cryogenic condenser.

Date of publication A3: 17.12.2003 Bulletin 2003/51

(43) Date of publication A2: 03.12.2003 Bulletin 2003/49

(21) Application number: 03011557.0

(22) Date of filing: 21.05.2003

(51) Int Cl.7: F25B 21/00, H01F 1/01

(84) Designated Contracting States:

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR

HU IE IT LI LU MC NL PT RO SE SI SK TR

Designated Extension States: AL LT LV MK

(30) Priority: 21.05.2002 US 151537

(71) Applicant/Inventor: Minovitch, Michael Andrew

Los Angeles California 90027 (US)

(72) Inventor: Minovitch, Michael Andrew

Los Angeles California 90027 (US)

(74) Representative: Manitz, Finsterwald & Partner GbR

Postfach 31 02 20, 80102 München (DE)

Patent number: US 2003/0218852 A1

Abstract

A method and apparatus is provided for generating an artificial heat sink below ambient temperature for a cryogenic condenser by isothermally magnetizing a paramagnetic fluid and removing the magnetic field thereby creating a temperature drop in the fluid by the magentocaloric effect. The heat of magnetization is converted into mechanical work by initially placing the fluid inside a sealed chamber with a door that opens to a conduit leading into the bore of a superconducting solenoid. When the solenoid is energized with current, it creates a strong axial magnetic field that exerts magnetic attractive forces on the fluid inside the chamber. When the fluid is released by opening the door, it is accelerated through the conduit toward the superconducting solenoid where it becomes magnetized by the increasing strength of the magnetic field. By mounting a non-magnetic turbine inside the conduit between the solenoid and the chamber, the kinetic energy of the accelerating flow stream, which is equal to the heat of magnetization, is converted into mechanical work thereby achieving isothermal magnetization. By removing the magnetic field after the fluid enters the bore of the solenoid, a temperature reduction is achieved thereby enabling the fluid to absorb heat in a cryogenic condenser.

Inventor: Minovitch, Michael, A.

2002-05-21: Priority to US10/151,537

2002-05-21: Application filed by Individual

2003-11-27: Publication of US20030218852A1

2004-05-25: Application granted

2004-05-25: Publication of US6739137B2