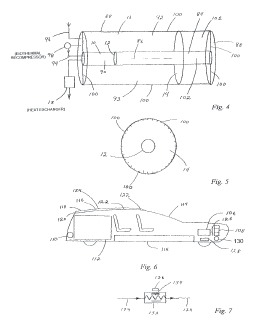

Closed Cycle Cryogenic Engine & Operating Method for Propelling Vehicles & Generating Electricity

- :

Publication number: US 2015/0369221 A1

Abstract

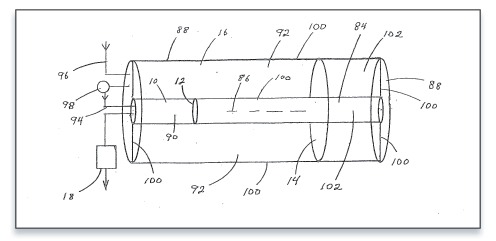

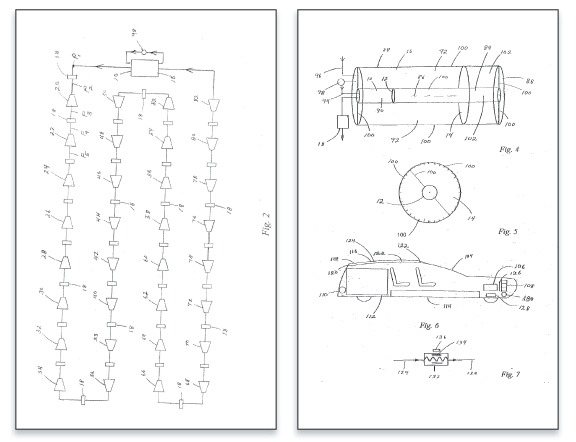

A closed-cycle cryogenic engine is provided for propelling vehicles or generating electricity at high power densities without consuming any working fluid. The engine comprises a working fluid having a high specific heat that remains in a gaseous phase. The high temperature heat reservoir is the natural environment and the low temperature heat reservoir is created artificially by evaporating water. By isothermally compressing the working fluid at low temperature by absorbing the heat of compression by evaporating water, it is possible to extract a large amount of natural heat energy from the environment and convert a large fraction of it into net output work. Since the latent heat of evaporating water is very high, very little water is consumed which represents the engine’s only fuel.

Type: Application

Filed: August 12, 1983

Date of Patent: August 24, 2015

Inventor: Michael A. Minovitch

Status: Active (2034-06-20 – Anticipated expiration)

Publication number: US 9/334,8541

Abstract

A closed-cycle cryogenic engine includes a high specific heat working fluid remaining in a gaseous phase. The high temperature heat reservoir is the natural environment and the low temperature heat reservoir is created artificially by evaporating water. Isothermally compressing the working fluid at low temperature by absorbing compression heat by evaporating water extracts heat energy from the environment, converting it into net output. A plurality of serially connected isentropic expanders is interposed with a like plurality of re-heating stages. The temperature difference between the high and low temperature heat reservoirs is a few degrees, allowing expansion operation with low expansion ratios, enabling a large number of expanding and reheating steps. Each engine cycle extracts natural heat energy from the environment, converting a large fraction into high density net output work. Very little water, the engine’s only fuel, is consumed since evaporating water’s latent heat is high.

Inventor: Minovitch, Michael, A.

2014-06-20 – Application filed by Individual

2014-06-20 – Priority to US14/120,711

2015-12-24 – Publication of US20150369221A1

2016-05-10 – Application granted

2016-05-10 – Publication of US9334854B2

2034-06-20 – Anticipated expiration

1Having previously published pre-grant publication.